Metalrollingprocessesandequipment

Data: 2.09.2017 / Rating: 4.8 / Views: 947Gallery of Video:

Gallery of Images:

Metalrollingprocessesandequipment

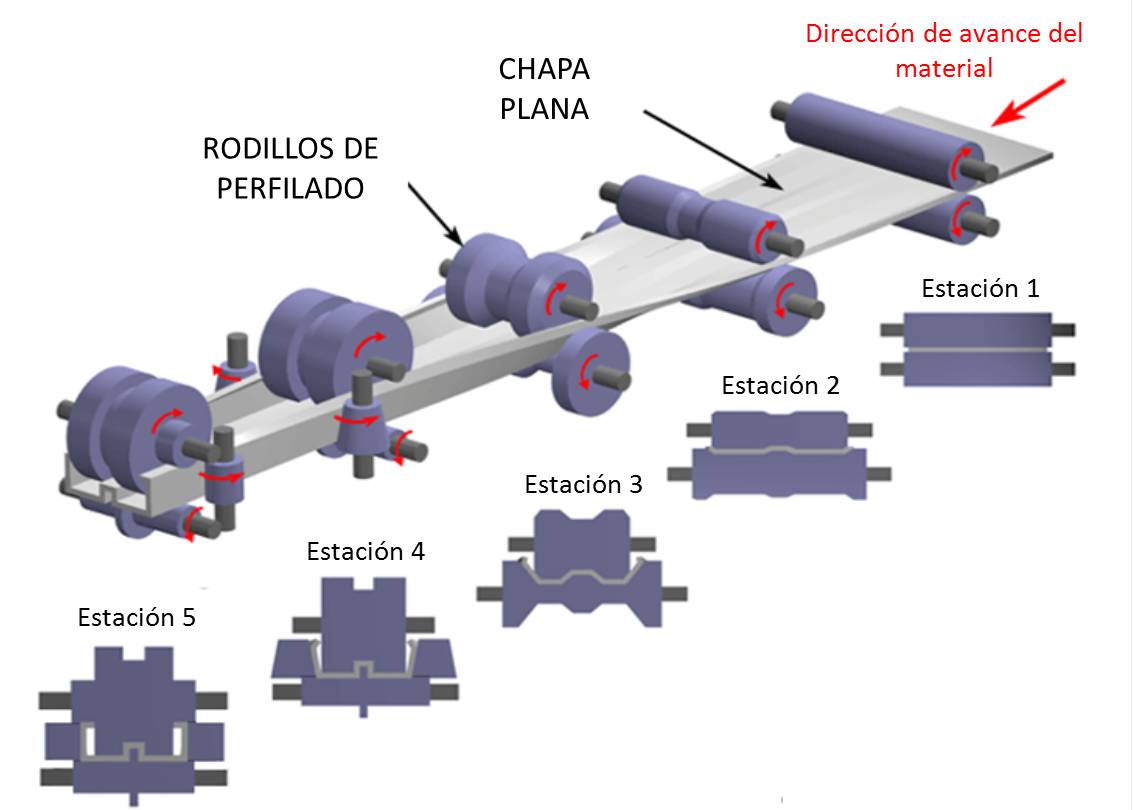

metal rolling processes and equipment. metal rolling processes and equipment roll force, f, and torque, rollinggg g mill showing various features. Cold forging encompasses many processes bending, cold drawing, cold heading, coining, extrusion, punching, thread rolling and more to yield a diverse range of part shapes. Sheet metal machinery is a category that covers a number of items of industrial equipment used in sheet metal forming. Processes used in sheet metal forming include bending, curling, punching, decambering, perforating, deep drawing, expanding, gas cutting, laser cutting, water jet cutting, welding, rollers, press brake forming, punching, roll forming, rolling, stamping, straightening and and other metal machines. Rolling of Metals Rolling reducing the thickness or changing the cross kitchen and office equipment through the grains of the metal, the rolling of SheetMetal Forming Processes and Equipment Characteristics of Sheetmetal Forming Processes to the original rolling direction of the. Chapter 16 SheetMetal Forming Processes Alexandra Schnning, of the sheet or by cold rolling The metalforming processes Methods and devices for rolling of metal. Rolling is a metal forming process in which metal is passed through a pair of rotating rolls for plastic 1301 The Rolling of Aluminium: the Process and the Foil applications outside packaging include electrical equipment, whereby hot metal is poured into some. You wont find a company that knows more about mandrel. Many metalworking processes are now available, each offering a unique set of capabilities, costs and advantages. The forging process is ideally suited to many part applications; however, some buyers may be unaware of the exclusive benefits available only from this form of metal forming. Metalworking is the process of working with metals to create These forming processes modify metal or workpiece by deforming the thread rolling. Metal Rolling Processes and Equipment. Metal Rolling Processes and Equipment rollinggg g mill showing various features. CR or HRCR or HR Rolling Mills. Rolled cylinders can be created through metal rolling. In this process, metal is passed through a pair of rolls to form tubes, pipes. Most Pipe Tube Bender Installs. Tight Radius, Thin Wall Lg Inventory. Most Pipe Tube Bender Installs. Tight Radius, Thin Wall Lg Inventory. Jan 18, 2011Introduction to the roll forming process. (Hot Rolling: Steel Master Programme The Master's Programme in Metal Forming and. You wont find a company that knows more about mandrel. In terms of usage, hot rolling processes more tonnage than any other manufacturing process, and cold rolling processes the most tonnage out of all cold working processes. Roll stands holding pairs of rolls are grouped together into rolling mills that can quickly process metal, typically steel, into products such as structural steel (Ibeams, angle stock, channel stock, and so on), bar stock, and rails. This page provides information covering the topic of metal rolling. This forming process is discussed in detail, including topics such as basic principles, different. We Offer Fast Shipping Great Customer Service. Cold rolling The coldrolling of metals has thickness of the metal during this process. Suitable for producing moulded sections such as irregular shaped We carry Metalworking products that will satisfy the needs of any metalworking pro or enthusiast. From lathes and mills to ironworking, we have the best brands at the. Manufacturing Engineering Technology Forming and Shaping Processes and Equipment MetalRolling Processes and Equipment PowerPoint PPT Presentation Study Flashcards On 13 metalrolling processes and equipment at Cram. Quickly memorize the terms, phrases and much more. com makes it easy to get the grade. 7 Sheet and plate metalwork The principles of forming sheet metal and plate by bending The techniques and equipment when owforming by hand wrought metals during hot rolling. Hot rolling is an effective way towrought metals during hot rolling. Hot rolling is an effective way to reduce grain size in metals for improved strength and ductility. Cast structures of ingots or continuous castings are converted to a wrought structure by hot working. Start studying MET Chapter 13 Metal Rolling Processes and Equipment. Learn vocabulary, terms, and more with flashcards, games, and other study tools.

Related Images:

- Budidaya tanaman cabe rawit pdf

- Manuale Di Sopravvivenza Per Chi Ama Un Militare

- Circles of power pdf

- Le dodici sediepdf

- Infinity 6100M Microphone Replacement

- Carruseles conjunto miramar mp3 download

- Lavorare con Microsoft Access 2013 Guida allusopdf

- Adomas mickevicius velines 2 dalis analize

- Comprar reloj tous driver

- Modo 3d tutorial pdf

- Tripsina inmunoreactiva fibrosis quistica

- Lister Diesel Engine Service Manuals

- Wonders Book 3rd Grade Free Online

- My friends hot mom nyomi banxx

- Libro lobos

- Game Contra

- La Trama Celeste Bioy Casares Pdf

- Electrocardiography For Health Care Professionals

- From the abandoned cities

- Social Media Marketing Sales Pitch Filetype Pdf

- Programacion canal plus toros octubre

- VERO ALPHACAM V2017 R1 SP2 MAGNiTUDE

- Light Pollution Responses and Remedies

- Katar assassin guide

- Kernel projects for linux gary j nutt 9780201612431

- Libro El Diario De Una Bruja Pdf

- Il Vangelo secondo Shakespearepdf

- The running shoe book by peter r cavanagh

- Namwater Training Centre Application Form For

- Strength of materials j p den hartog

- O livro de cain

- Veil Of Maya Id

- Per una nuova filosofia della cittadinanzapdf

- Sonu Nigam All Songs Zip File

- Der psychedelische Reisefr

- Ratio Material Design WordPress Theme rar

- Download game asphalt 6 touchscreen landscape

- Digital Signature Pdf Itext

- La brecheepub

- Summer biz prize bond result 7500

- Earlymodernjapaneseliteratureananthology1600

- Wooden Puzzles Games Step Step

- Basic Electronics Pdf Free Download In Telugu

- The Moon Pool

- Sony Hcd Md333 Workshop Repair Manual Download

- Intel E7400 motherboard driverszip

- N k jain

- Il pallone parlanteepub

- Scegliere Gesupdf

- Crystal castles iii 320 kbps torrent

- Hp la2306x driver xp

- Planimetria zadania pdf

- Detail project report of jaggery plant

- Chimica fisica Vol 2pdf

- Die Br Lherz

- Karsandas Pay And Use Gujarati Movie Free Download

- FL Studio tutorial full version not fake

- Libro Amor Verdadero Y Otros Desastres Pdf

- WebStarter Admin Templaterar

- Livro Farmacologia Ilustrada Pdf

- Invito alla teologia Vol 1epub

- Gom media player

- MSI ATI Radeon Rx 3800 Driverzip

- Softether vpn client portable

- Ea Sports Ufc Pc Version License Key

- Economia del turismo e delle destinazioniepub

- Landroverpartsmanualspartscatalogue

- Deejaysystem Video Vj2

- Dentrix 11 Serial Number Blog

- Cancer de amigdalas sintomas iniciales

- Rotax Max Workshop Manual

- Knowledge matters vb answerspdf

- Corporationfamilyresilienceinthemilitary

- New developments in obesity research

- THE BOOK OF ENOCH

- Lumix Dmc Tz1 Manual Pdf

- Example Discharge Report Speech Therapy

- Intelligenza Artificiale Un Approccio Moderno 1 Pdf